E-Brake C-200T Tool Mate: Revolutionizing Bending with an Automatic Tool Changer

Unlock enhanced efficiency and precision in your fabrication process with the E-Brake C-200T Tool Mate. A powerful automated press brake equipped with an advanced automatic tool changer. Designed for manufacturers who need high productivity, rapid setup times, and superior precision, this cutting-edge press brake offers seamless automation for your bending operations.

What is an Automatic Tool Changer?

An automatic tool changer (ATC) is an advanced system that allows for the automatic swapping of tools on a press brake without manual intervention. This feature greatly reduces downtime during job changes and minimizes the need for operator involvement, improving overall efficiency. The E-Brake C-200T Tool Mate integrates this technology to ensure rapid tool changes, increased productivity, and flawless bending results.

Key Features of the E-Brake C-200T Tool Mate with Automatic Tool Changer

Automatic Tool Changing for Increased Efficiency

The SafanDarley E-Brake C-200T is equipped with a high-performance automatic tool changer that allows for quick and precise tool swaps. This automation significantly reduces setup times, enabling faster transitions between different parts and enhancing overall production efficiency.Enhanced Productivity with Minimal Downtime

With the automatic tool changer, the E-Brake C-200T minimizes manual intervention and idle time, ensuring that your press brake is running as efficiently as possible. The system reduces downtime between jobs, improving throughput and helping you meet tight production deadlines.Precision and Consistency in Bending

The integration of the automatic tool changer ensures that each tool is loaded and positioned with pinpoint accuracy. This leads to consistently high-quality bends with minimal variation, even during high-volume runs.Flexible and Scalable for Diverse Applications

Whether you are working with small or large parts, the E-Brake C-200T Tool Mate adapts to your production needs. The system can handle a wide variety of bending operations, making it ideal for both short and long production runs.Reduced Labor Costs and Improved Safety

By automating the tool-changing process, the E-Brake C-200T reduces the need for manual tool handling, improving safety and reducing labor costs. Operators can focus on higher-level tasks, while the automatic tool changer handles the repetitive work.

Why Choose the E-Brake C-200T Tool Mate with Automatic Tool Changer?

The E-Brake C-200T Tool Mate offers an advanced solution for businesses looking to enhance their bending capabilities with automation. The automatic tool changer is a game-changer, streamlining your workflow, improving productivity, and ensuring consistently high-quality results with every bend.

Benefits of an Automatic Tool Changer in Press Brakes

- Faster Setup and Tool Changes: The automatic tool changer allows for rapid switching between tools, minimizing setup times and increasing overall productivity.

- Higher Precision: Automation ensures that tools are loaded with exceptional accuracy, resulting in precise bends and consistent quality.

- Reduced Manual Labor: By automating the tool change process, the need for manual labor is significantly reduced, allowing operators to focus on more complex tasks.

- Improved Production Efficiency: The ability to change tools quickly and accurately helps reduce downtime and optimize production cycles.

- Safer Work Environment: With fewer manual tool changes, the risk of operator injury is minimized, creating a safer workplace.

Transform Your Bending Operations with an Automatic Tool Changer

The E-Brake C-200T Tool Mate is the ideal solution for manufacturers looking to increase efficiency, reduce downtime, and ensure precise, high-quality bending. By incorporating advanced automation into your press brake, you can streamline your operations and stay competitive in today’s fast-paced manufacturing environment.

Ready to revolutionize your bending process? Contact Modern Machinery today to learn more about the E-Brake C-200T Tool Mate can transform your production line.

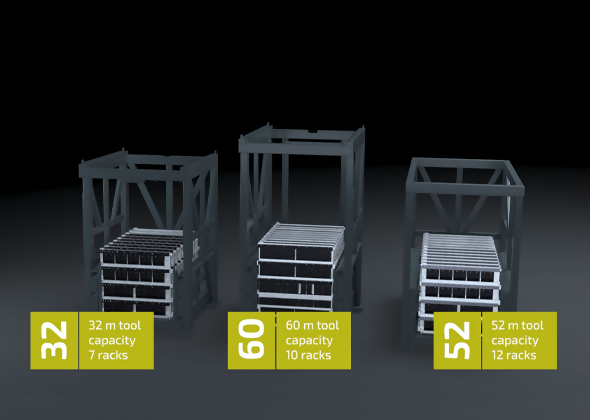

Large storage capacity

The tool storage magazine is positioned to the left of the press brake and has a capacity of 32, 52 or 60 metres, which gives extensive storage for a variety of Upper and Lower tools.

The shuttle collects the tools from Tool-Mate, after which they are placed in the correct position on the machine. The tool rotation station allows the top tools to be rotated 180 degrees, enabling tools to be used both ways thus eliminating the need for a double tool set.

User-friendly & accurate

The Tool Mate works very intuitively and does not require extensive training. The SafanDarley E-Control controls tool changes from start to finish. The correct tool setting can be loaded and used directly on the machine from AutoPOL offline software (or any other independent offline bending simulation software program).

The high-precision changer ensures that the tools are placed in exactly the right position. The laser on the changer then checks the end position of the tool set-up, so that a correct tool set-up is guaranteed.