The Schroeder Group has committed itself to the task of enabling the highest quality and efficient processes in the manufacture of sheet metal products. Founded over 70 years ago and for three generations, everything in their family business has revolved around the fascination of sheet metal processing. Their strengths are the innovative strength of design and development, including control software, as well as the high level of vertical integration. Schroeder sheet metal folding and bending equipment can be optionally expanded based on conveniently equipped basic models. With numerous equipment variants to customer-specific solutions, they meet almost every requirement needed.

Not what you are looking for? Take a look at our complete line of press brakes.

Advantages of Folders

In today’s manufacturing environment you need to make every operation in your shop as efficient as possible. Schroder sheet metal folders offer many advantages over traditional press brakes take a look;

- Fast setup, makes your press brake more efficient

- No marking on polished, painted or sensitive material

- Larger parts are easily run by a single operator

- Superior ergonomics, parts are supported by the backgauge

- Blank inaccuracy is corrected on the 1st bend

- One set of universal tooling for the life of the machine

- Programming and operation by non-skilled operators

- Main part of sheet on the backgague during folding

- Less risk of collision with the operator during folding

- It’s a green solution

Schroder Evo Center

The highly automated EVO-CENTER with ATC (Automatic Tool Change) gives you complete control over your bending needs. A single set of 15-3/4” tools that are automatically changed drastically reduces setup times while increasing the flexibility and part potential. Eliminate part flipping, part whip, and multiple operators with bi-directional folding and ergonomic automation. Since material variance has virtually no impact on part accuracies, you get parts with superior quality, and automated operation removes operator influence over part quality, and output.

Features

- Semi-automatic up and down folding

- Fully-automatic tool change (ATC)

- Highest level of automation on a folding machine without using a robot

- Movable display via guide rail

- Easy to use software with touchscreen control

- Two independently controlled and movable tables

- Automatic alignment with rotating plate

Schroeder Powerbend Universal

Schroeder PowerBend Universal name speaks for itself: This folding machine is designed to meet the demands in a wide range of applications. Its flexibility through applications up to 4 mm steel is the result of decades of experience in industrial sheet metal folding. A perfect balance between technology and performance. It was engineered using state of the art tools and finite element analysis.The Nano Touch software makes it the perfect machine for a wide array of production requirements. The control system is easy for anyone to program profiles and parts for quick production changes.

Features

- Semi-automatic and fully automatic of one side

- Increase productivity with up and down folding

- Control remote maintenance

- User-friendly visual programming on touchscreen monito

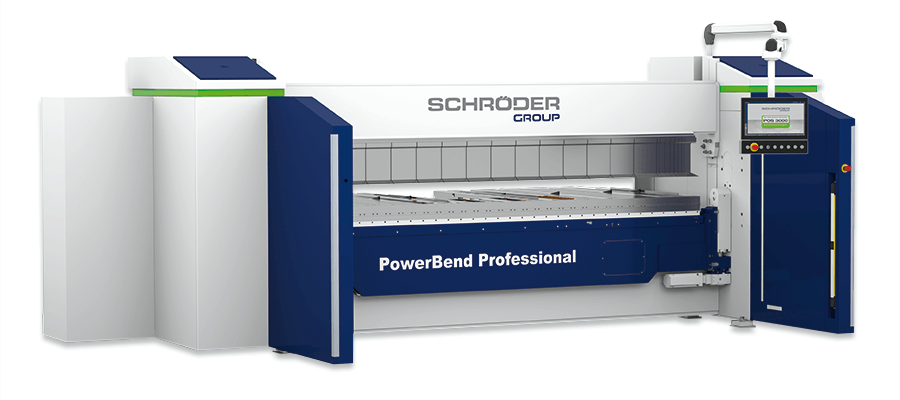

Schroeder Powerbend Professional

The NEW PowerBend Professional is the next generation to the incredibly successful PowerBend series of thin gauge sheet metal folders. Thanks to the superior drive technology, advanced electronic controls, CNC crowning, and segmented tooling options, the PowerBend Professional possesses the robustness, reliability, and accuracy to handle complex geometries and difficult bending requirements with ease. At the same time the PowerBend Professional offers the flexibility your company needs to produce short runs and prototypes. With the hydraulic tool clamping device and the optional rotating clamping beam, set up times can be drastically reduced. The result is a considerable increase in productivity, and a significant reduction in labor.

Features

- Extremely rigid machine body for highest precision and performance

- Fast changeover with rotating clamping beam

- Hydraulic tool clamping

- Flexible gauging and table options

- Semi-automatic and fully automatic of one side

- Increase productivity with up and down folding

- Control remote maintenance

- User-friendly visual programming on touchscreen monitor

Schroeder Powerbend Industrial

The robust design of the PowerBend Industrial folds ¼” mild steel at 10’ lengths, and 0.196” mild steel at 13-1/2’ lengths. The standard 650 mm (25.6”) of stroke and open supports a maximum tool height of 300 mm (11.8”) creating a huge part envelope. Vacuum grip and feed gauging systems, CNC crowning, dual monitors, and tool positioning lights are just a few of the standard features on this revolutionary advancement in machine design. Bigger, stronger, and more capable in every way but still a perfect blend of performance and price point.

Features

- Unique robustness, reliability and repeat accuracy

- Production of single pieces and prototypes

- Patented, hydraulic Up-and-Down system

- Clamping beam stroke of 650 mm

- Tool positioning display alongside the clamping beam

- Bilateral drives on the clamping-and the folding beam achieve extremely fast clamping and folding speeds

- Two touch-panels for easy operation from the front and the rear side of the machine

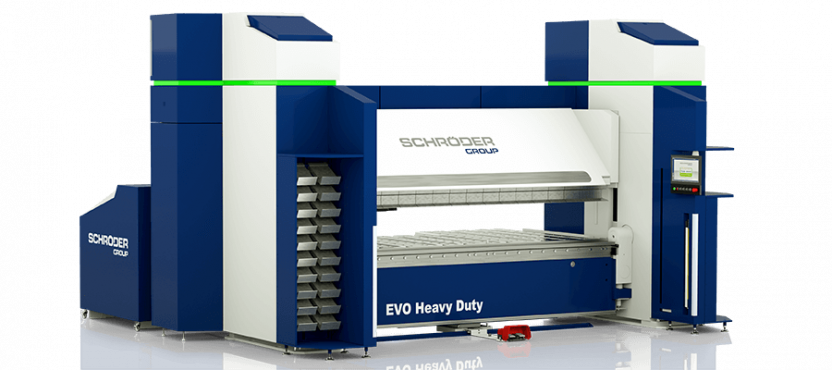

Schroeder EVO Heavy Duty

The new EVO Heavy Duty from Schröder is the only folder of its kind. The newest addition to Schröder’s wide range of industrial folders can fold up to 5/8″ mild steel and 1/2″ stainless to a 10′ bending length. Able to form any thickness of material from max capacity down to shim stock with a single tool set, the versatility of this model is unmatched. Multiple gauge options that include a gripping system that automatically feeds your profiles through the bending sequence offers production advantages beyond that of any other method of bending. Get rid of multiple operators and dangerous conditions of handling thick plate, and let the machine do the work.

Features

- Strongest folding capacity in the industry up to 5/8” mild steel

- Minimal set-up time

- Great flexibility and variability due to extensive equipment options

- Unique robustness, reliability, and repeatability

- High productivity due to easy handling of workpieces

- Offline-programming and innovative CAD/CAM concept thanks to Schroeder Unfold

Schroeder SPB Evolution

The SPB Evolution with universal tooling gives you total flexibility from a single tool set, drastically reducing tool change, with greatly increased part profile capabilities. Eliminate part flipping, part whip, and multiple operators with bi-directional folding and ergonomic automation. Since material variance has virtually no impact on part accuracies, you get parts with superior quality, and automated operation removes operator influence over part quality. If you want the capability to go from part to part to part in today’s demanding environment, Schroeder is a great choice.

Features

- Up-and-down technology reduces processing times

- Rotating clamping beam, fast change between jobs or for complex folding

- Minimal set-up time

- Optional automatic tool changeout

- High productivity due to easy handling of workpieces

- Offline-programming and innovative CAD/CAM concept thanks to Schroeder Unfold

Schroeder Bending Center

On request, Schroeder specialists in sheet metal working, design special machines that will improve the efficiency for your individual production processes. High performance swivel folding machines are the foundation of our semi- and fully automated Bending Centers. Building on the Schroeder technology, hardware, and software, they develop individual sheet metal working solutions that range from customized machines, through various steps of automation and extend to fully automated production lines that run 24 hours a day. The Schroeder bending centers are based on their modern folding machines from the Evolution-Series. These machines are already fast and extremely efficient in normal operation conditions with manual product placing. In the center of an automated solution their strength can be even more extended. Extremely robust and with very low maintenance needs these machines are perfect for continuous use.

Features

- 24/7 hours operation

- Large-volume series production

- Improved manufacturing process

- Utmost repeatable accuracy

- Automatic tool changing