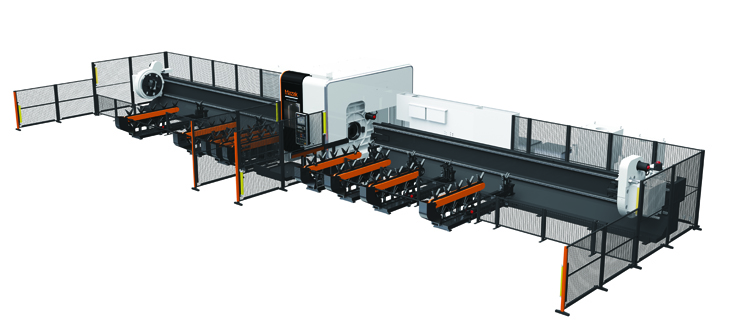

Available in two models, the Mazak Fabrigear’s are the ideal laser cutting machines for fabricators who process tube and pipe. The FabriGear 220 can process up to 8.6″ round or 6″ square pipe up to 39′ long, while the FabriGear 400 can process up to 16″ round pipe or 11.8″ square pipe and up to 49′ long.

Benefits of the Mazak FabriGear

- Cuts a large range of tube and pipe, whether round, square, rectangular, triangular, I and H-beams, C-channel, angle iron, and additional user-defined shapes

- Cut at any desired angle for weld prep and easy fit-up of assemblies

- Requires minimum labor input for small to large volume part production

- Powerful, 6-Axis laser with automated load/unload functions. Handles mill-length pipe and structural material.

FabriGear Specifications

Resonators: 2500W or 4000W

Applications: Laser tube cutting as well as, pipe, and structural shapes in one setup

Capacities: Up to 16″ round pipe or 11.8″ square pipe up to 49′ long

Features: Automatically loads, feeds, laser cuts and unloads parts

The Mazak FabriGear is the Perfect Solution for Laser Tube Cutting

The Mazak Fabrigear performs laser tube cutting, whether round, square, rectangular, or triangular. In addition, it can completely process I and H-beams, C-channel, angle iron, and additional user-defined shapes.

With 6-axis laser tube cutting you can cut at any desired angle for weld prep, plus achieve the highest accuracy for easy fit-up of assemblies – all in a single program cycle. Moreover, FabriGear’s program-controlled loading, workholding, and unloading make it a super-efficient laser tube cutting cell requiring a minimum of labor input.

With 26′ of standard length capacity, the Mazak Fabrigear accommodates standard mill lengths. And an extra-long model is available to handle materials up to 49′ in length.

The FG CAM programming software is easy to use with illustrated fill-in-the-blank screens for quickly generating NC code. It performs dynamic nesting and has over 70 pre-programmed cutting parameters for you to choose from. In addition, fabricators can store their “best practices” and frequently used setups for even faster programming.