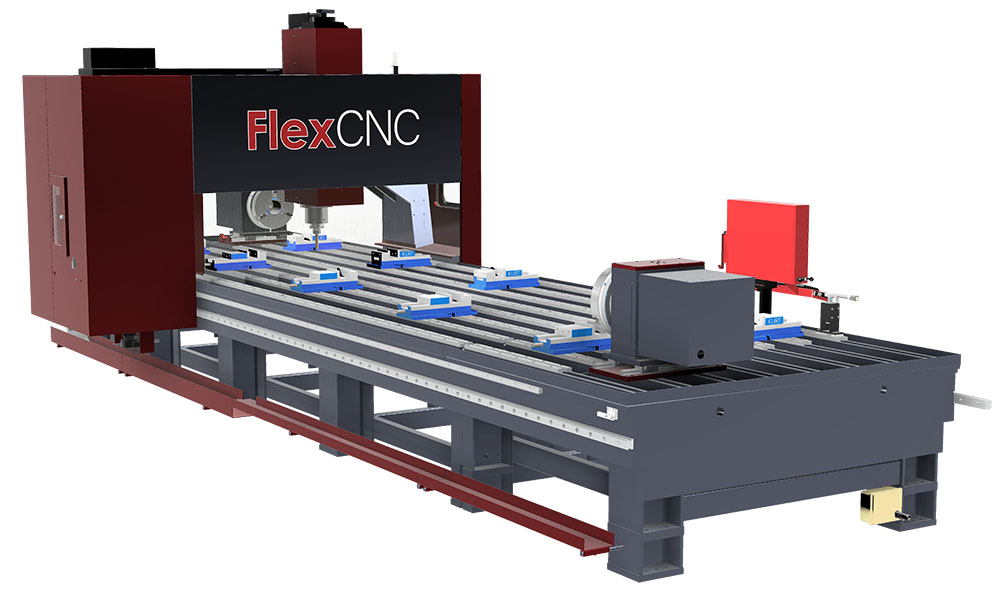

FlexCNC Vertical Machining Centers are the most flexible and affordable vertical machining centers on the market today. They can be customized to fit your shops requirements including custom bed lengths and the ability to handle a multitude of setups on one machine. The FlexCNC will help you increase your shops throughput to help you make more parts and in turn, make more money.

Benefits of the FlexCNC

- Zero Weight Restrictions – The FlexCNC has a stationary bed on a mono-block welded steel frame. Unlike other VMC’s where the table moves, the FlexCNC’s spindle moves while the bed is stationary, eliminating the need for any bed weight restrictions.

- Not Limited by Bed Size – When it comes to bed size, the FlexCNC starts where other VMC’s stop. The FlexCNC bed length starts at 10ft and goes up to 80ft to easily accommodate a wide range of long parts.

- Open Bed for Easy Loading and Unloading – Traditional VMC’s require the operator to reach into the machine to load their next part. The FlexCNC has an open bed, so loading is as simple as bringing the part over top of the machine and setting it down. Heavy loads can easily be placed onto the machine bed with an overhead crane.

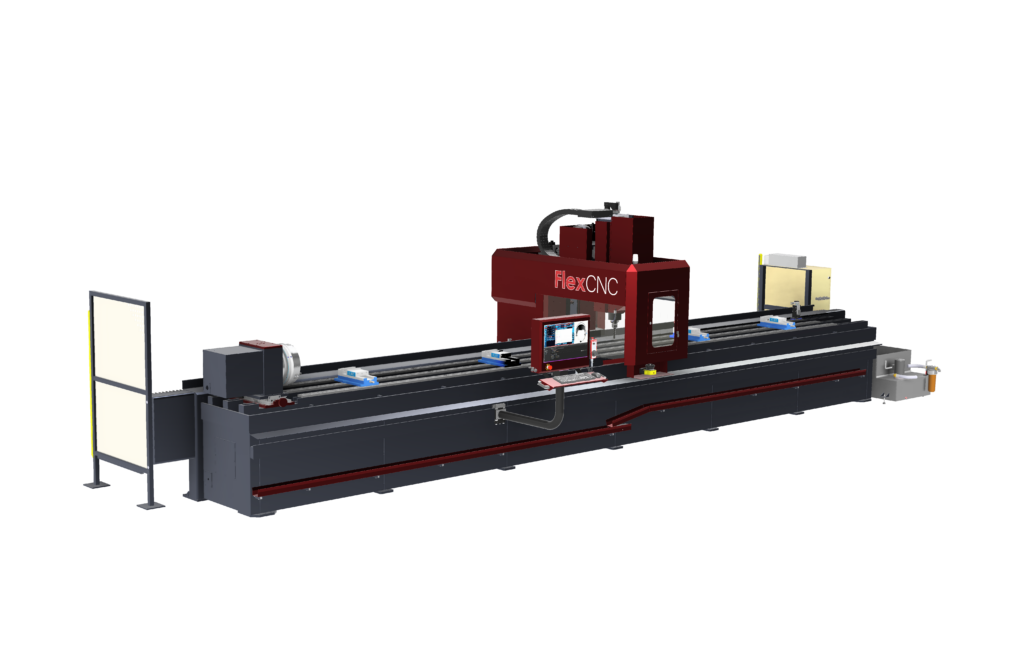

C Series FlexCNC Up to 80 feet on the X Axis

Capable of high-speed drilling and milling of your large parts in one setup with less repositioning. It is available in two different spindle tapers; CT/BT40, with a maximum torque output of 122 ft/lbs. The C-Series features a monobloc, welded steel frame with high rigidity, and a T-slot machine bed for easy fixturing. The machine is moved along two oversized precision linear guideways on each axis and it includes dual drive on the X-axis with a high precision helical rack and an oversized ball screw on the Y & Z-axis. Our motion control system is the most state-of-the-art CNC controller available, giving you the capability and Flexibility for your machining applications large and small. Custom sizes available.

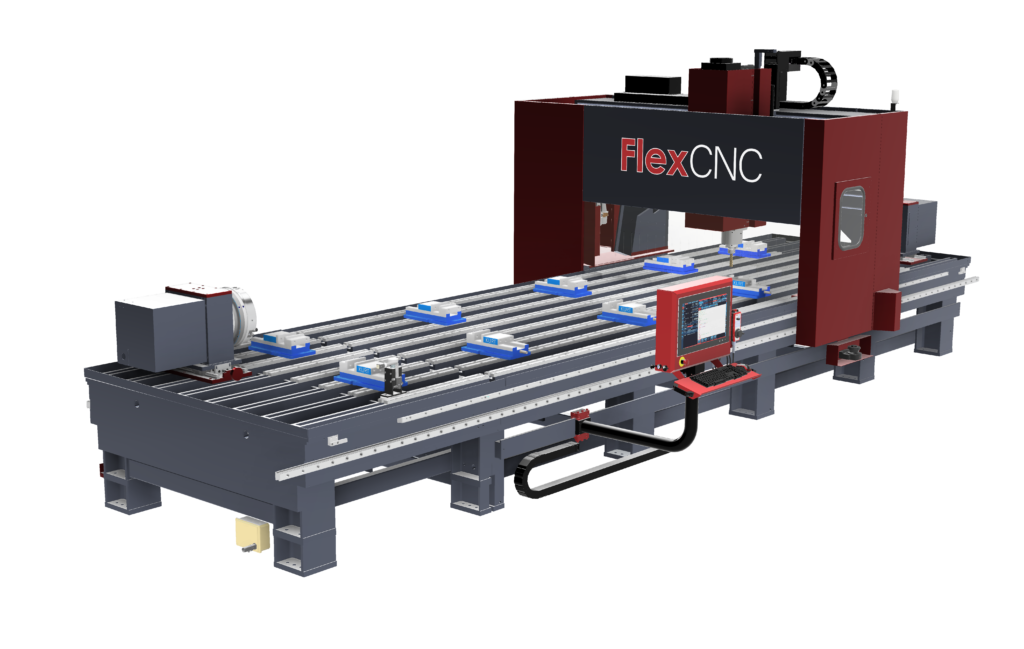

G Series FlexCNC XY Axes Up to 50′ x 10′

Capable of high-speed drilling, and milling of your large parts in one setup with less repositioning. It is available in four different spindle tapers; CT/BT40, CT/BT50, with a maximum peak torque capability of 368 ft/lbs. The G-Series features a monobloc, welded steel frame with high rigidity, and a T-slot machine bed for easy fixturing. The machine is moved along two oversized precision linear guideways on each axis and it includes dual drive on the X-axis with a high precision helical rack and an oversized ball screw on the Y & Z-axis. Our motion control system is the most state-of-the-art CNC controller available, giving you the capability and Flexibility for your machining applications large and small. Custom sizes available.

Standard Features of Both C and G Series Machining Centers

- Hand Pendant

- 22″ Touch Screen

- Omron FlexCNC Controller

- Mobile Control Panel

- Through Spindle Coolant

- Auto Tool Changer

- Flood Coolant

- Tool Calibrator

- LED Machine Light

- Ethernet Connection

- Safety Laser Scanner on Front of the Machine

- Light Barrier on the rear of the Machine

- 90 Gallon Coolant Tank

- Chip Auger & T-Slot Rails