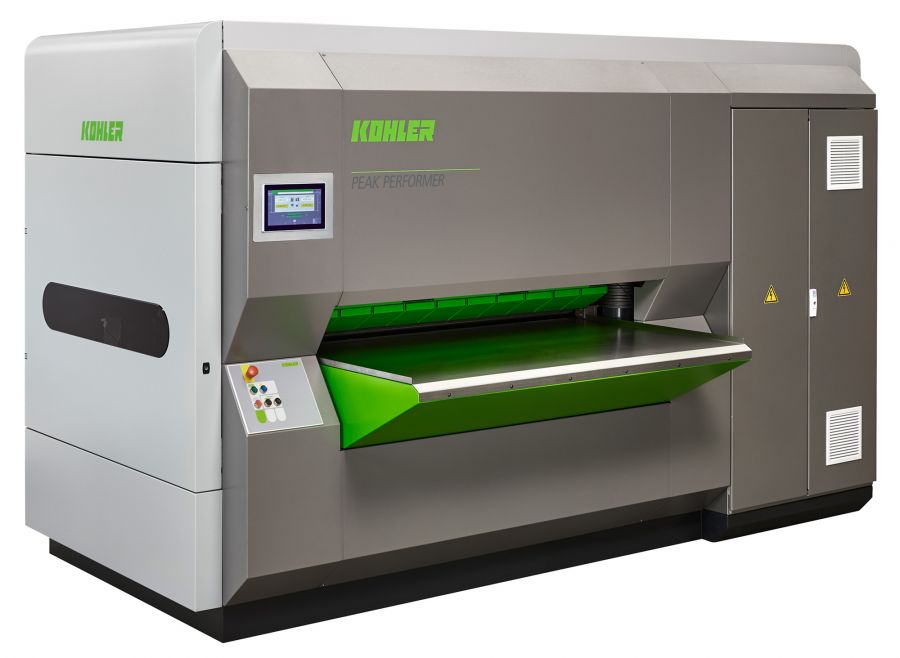

Why Level?

Irrespective of the size and material, sheets need to be leveled after cutting to size. This is because tension-free sheets are a precondition of achieving the absolute best quality in downstream manufacturing processes when welding, bending, or assembling. Precise leveling with a roller leveling machine produces sheets that are level and largely free of stresses.

Efficient Welding

Leveled parts speed up both automated and manual welding processes, since the welding gap is more constant due to leveling of the material having been leveled. The use of leveled and therefore low-tension parts means they remain flat during welding. This reduces the pre-work required and the end product is more stable.

Reproducible Bending Process

Leveled materials provide for more constant elastic recovery in the bent component. The stresses created within the initial material by the rolling direction are removed by leveling. Two benefits result from this. Firstly, less rework is required, and secondly, the bending process is reproducible and allows for automated production. Rework becomes a thing of the past!

More Precise Assembly

Materials that are straight and dimensionally stable are also a key aspect in assembly operations. Materials that were previously leveled can be assembled more quickly and precisely. The product will also be of higher quality both optically and technically.