Highly accurate and lightning fast tool changes

- Fast tool setup

- Use of V-Die 5mm to 70 mm

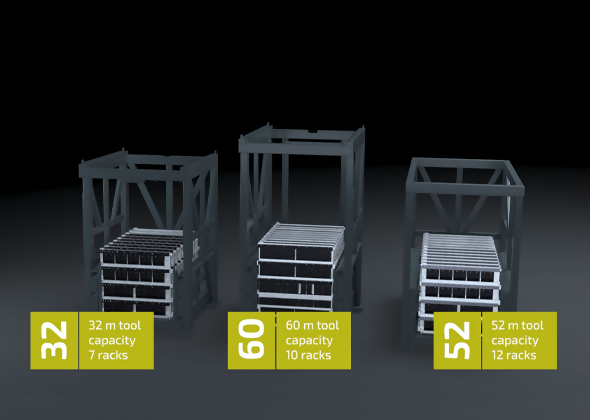

- Large tool storage capacity 32-52-60 metres

- Very user-friendly

- 100% electric press brake

- Automatic tool cleaning

- Always correct tool setup

- Intelligent tool configuration

- Rotating station to rotate top tools 180 degrees

Fast and efficient production

The E-Brake C 200T Ultra Tool Mate is equipped with an automatic tool changer. This tool changer ensures the automatic placement of the tools in the machine and thus provides extra efficiency and productivity. Whilst the Tool Mate changes tools, other work can be performed. This saves considerable time, especially for small batches. The continuous safety control in the safety zone allows the changer to change the tools at very high speed. For long tool setups, part tools with lengths up to 515 mm can be used.

With a new job, tools are changed automatically, the intelligent software makes only the necessary changes and tools from the previous tool set-up are reused. This results in shorter changeover times and improved productivity.

Large storage capacity

The tool storage magazine is positioned to the left of the press brake and has a capacity of 32, 52 or 60 metres, which gives extensive storage for a variety of Upper and Lower tools.

The shuttle collects the tools from Tool-Mate, after which they are placed in the correct position on the machine. The tool rotation station allows the top tools to be rotated 180 degrees, enabling tools to be used both ways thus eliminating the need for a double tool set.

Specifications Tool Mate

| max. V-opening | 2.75” |

| max. Die working height | 5.90” |

| max Upper tool working height | 7.87” |

| Min. Length | 0.78” |

| Max. Length | 20,27″ |

| Place tools longer than 125mm (4.9”) above and 250mm (9.8”) below | 4 sec |

| Placing top tool < 125mm (4.9”) | 8,5 sec |

| Remove tool | 1 sec + place |

Technical information

| Model | Tonnage | BowLength | Pressure force in US Ton | Cutting length in inches | Maximum stroke in inches | Q-dimension in inches | Closing speed in inch/min | Bending speed max. in inch/min | Return speed in inch/min | Motor power in kW | Weight in lb |

|---|---|---|---|---|---|---|---|---|---|---|---|

| E-Brake C 200T Ultra | 200 | – | 220 | – | 12 | – | 177 | 48 | 177 | 22 | – |

– EC20 Control, dual touch screen on swivel arm, height adjustable.

– EC Profiler bending simulation with automatic bending sequence calculation.

– Viewer for AutoPOL, Radan and Metalix graphic files.

– Y1/Y2 axis, CNC controlled.

– X-axis, CNC controlled.

– R-axis, CNC controlled.

– Z1 & Z2 axIs, type H, CNC programmable lateral adjustment of the backgauge fingers, independently adjustable

– Backgauge dX-axis adjustment. Type H. Stroke 200 mm. (+/- 100 mm.), on Z2, incl. 3D inserts.

– AKAS 5PM, CNC programmable.

– NSCL-II HC Premium. Top tool adapter with hydraulic clamping, with hardened surfaces. incl. hydraulic unit.

– NSCR-II HC Premium. CNC controlled crowning system with hydraulic lower tool clamping. incl. V-Lock.

– E-Bend L Blue Angle Measuring System.

– Swivel arm detection sensor.

– Tool lighting at the front.

– 2 movable support arms (stainless steel) with lateral T-slots.

– 2 back stops;

– For E 200-4300: Q size 690mm

– Tool Mate 32, 52 or 60 meter tool storage capacity

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

User-friendly & accurate

The Tool Mate works very intuitively and does not require extensive training. The SafanDarley E-Control controls tool changes from start to finish. The correct tool setting can be loaded and used directly on the machine from AutoPOL offline software (or any other independent offline bending simulation software program).

The high-precision changer ensures that the tools are placed in exactly the right position. The laser on the changer then checks the end position of the tool set-up, so that a correct tool set-up is guaranteed.